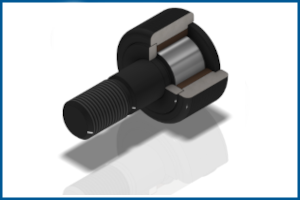

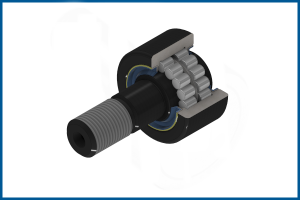

Carter Product Offering

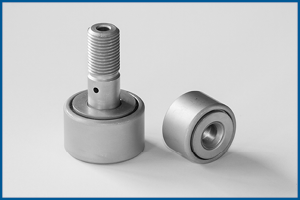

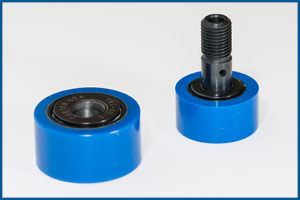

Carter Manufacturing has been producing bearings in Grand Haven, Michigan for over 50 years. We have a full line of standard cam followers and cam yoke rollers, including a larger variety of specialty items such as stainless steel, chrome-plated and poly-coated bearings than anyone in the industry.

At Carter, we specialize in custom solutions and customer service. Our inside sales team, engineering, production, and inventory are all located under the same roof, helping us to sustain some of the fastest lead times in the industry on special bearings.

Need a Bearing for a Special Application?

Creating custom solutions or modifying a standard product is our SPECIALTY! Lots of bearing manufacturers can offer you a custom solution, but they can’t do it as quickly as CARTER! Our Engineering and Production is all under one roof, right here in the United States! We have the agility to create and produce a custom solution faster than our competitors, and at a lower cost!

Call 616.842.8760 and speak with one of our customer service reps for more information